Are soft core colored pencils better than regular colored pencils?

July 23, 2025 by [email protected]

Choosing colored pencils can confuse artists. Soft cores promise richer colors. But do they truly outperform regular ones? Let me share what thirty years in pencil manufacturing reveals.

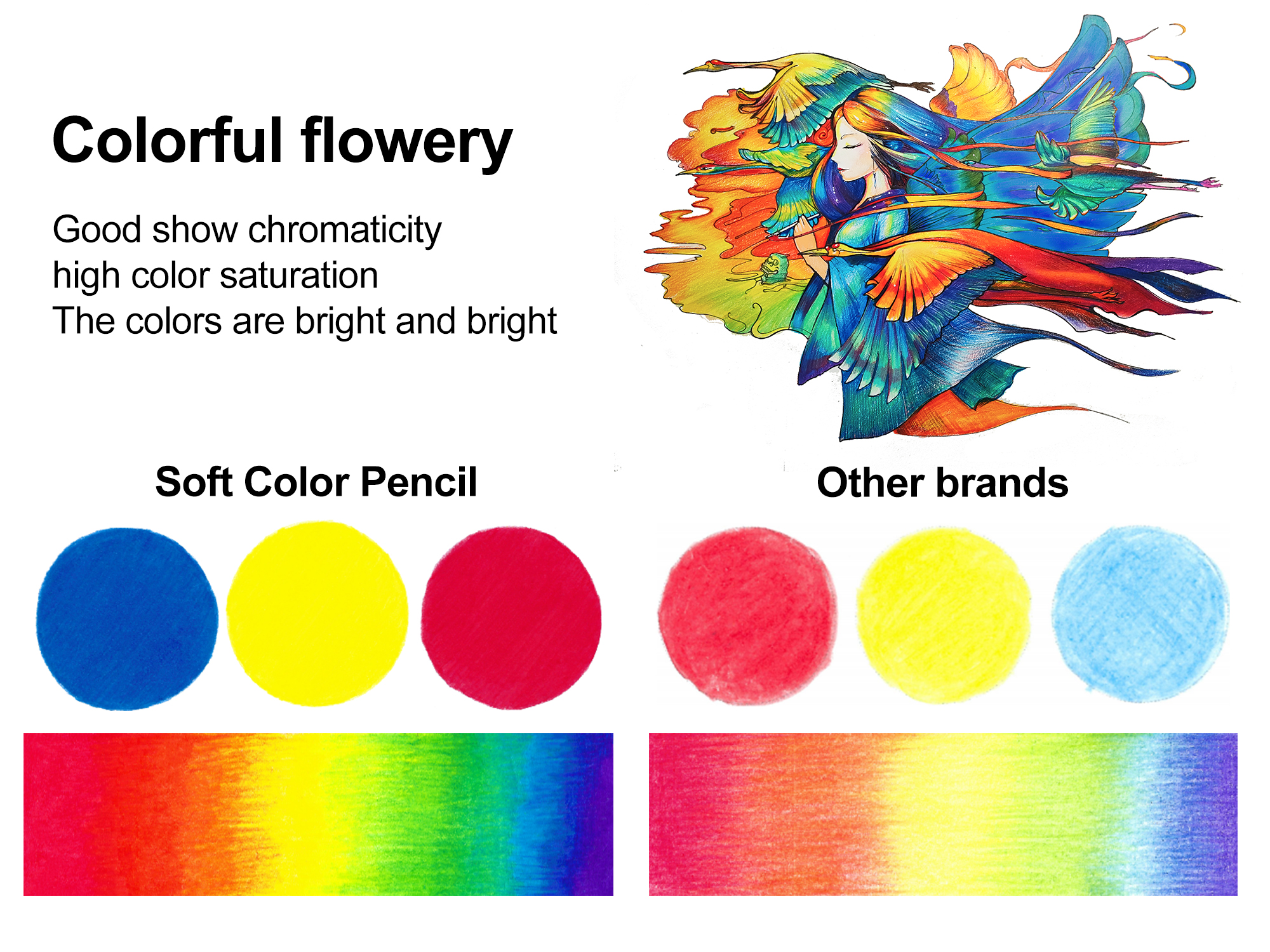

Soft cores lead in vibrancy and blending but trail in precision and durability. Soft versions deposit pigment faster but demand constant resharpening - regular pencils keep consistent fine lines with minimal intervention.

Remember how I struggled advising my Russian client? Their request for "soft" pencils meant something entirely different than what Japanese clients expect. Global standards vary wildly, making this question more complex than it appears. Now let's explore why regional preferences1 dramatically reshape what "better" means.

Understanding these differences transforms artwork. Read how professional artists select cores and why manufacturers tailor to regional demands.

What Are Considered the Best Colored Pencils?

Artists seek perfection in their tools. Yet defining "best" proves surprisingly difficult across markets.

The best pencils align with local artistic traditions and practical needs. Germany favors harder cores for precision line work, while Russia prizes ultra-soft cores for blending. Japan's gold standard? Balanced hardness for controlled vibrancy—neither too firm nor too creamy.

Three Factors Defining "Best" Across Markets

Quality standards shift dramatically across borders. Through exporting to 14 countries, we've identified key decision drivers:

-

Artistic Methodology:

- Russian oil-painting techniques demand blendable cores

- German technical drawing requires scratch-resistant precision

- Japanese manga relies on consistent mid-firmness

-

Performance Attribute:

| Performance Attribute | Impact on Artwork | Testing Method |

|---|---|---|

| Pigment Load | Color intensity and vibrancy | Single-layer application |

| Layering Capacity | Maximum color depth without mud | Overlapping strokes test |

| Core Stability | Break resistance during use | 45-degree pressure test |

| Blend Performance | Smoothness of color transitions | Gradient creation exercise |

| Lightfastness | Fade resistance over time | UV exposure measurements |

| Point Retention | Duration of sharp tip | Detailed line maintenance |

- Economic Tolerance:

- Emerging markets prioritize longevity over blendability

- Luxury art markets pay premiums for specialized cores

- Student-grade products dominate price-sensitive regions

Our Russian client first rejected our standard soft core, requiring a more expensive formulation to meet their ultra-soft expectations2. Meanwhile, our French luxury partner accepts soft cores' fragility for superior color depth3. There's no universal "best" pencil core any more than there's a universal painting style worldwide.

What Are Soft Core Colored Pencils?

Artists describe soft cores as "buttery" or "creamy." But chemically, they're engineered differently.

Soft core pencils contain elevated wax and pigment concentrations—typically 15-30% more than regular cores. This creates smoother application, richer color deposition, and superior layering capacity at the cost of faster tip erosion and higher breakage rates during shipping.

Manufacturing Secrets Behind Soft Cores

Having produced over 800 tons of soft cores annually, we engineer three critical properties:

The Pigment-Wax Matrix

Soft cores require careful wax selection. We combine:

- More delicate and high-quality wax for smooth application

- Carnauba wax for structural integrity

- Pigment loads up to 40% versus 25% in regular cores

Core Stability Challenges

Higher wax content makes cores:

- More temperature-sensitive during production

- Prone to bending if cooled improperly

- Vulnerable to impact fractures

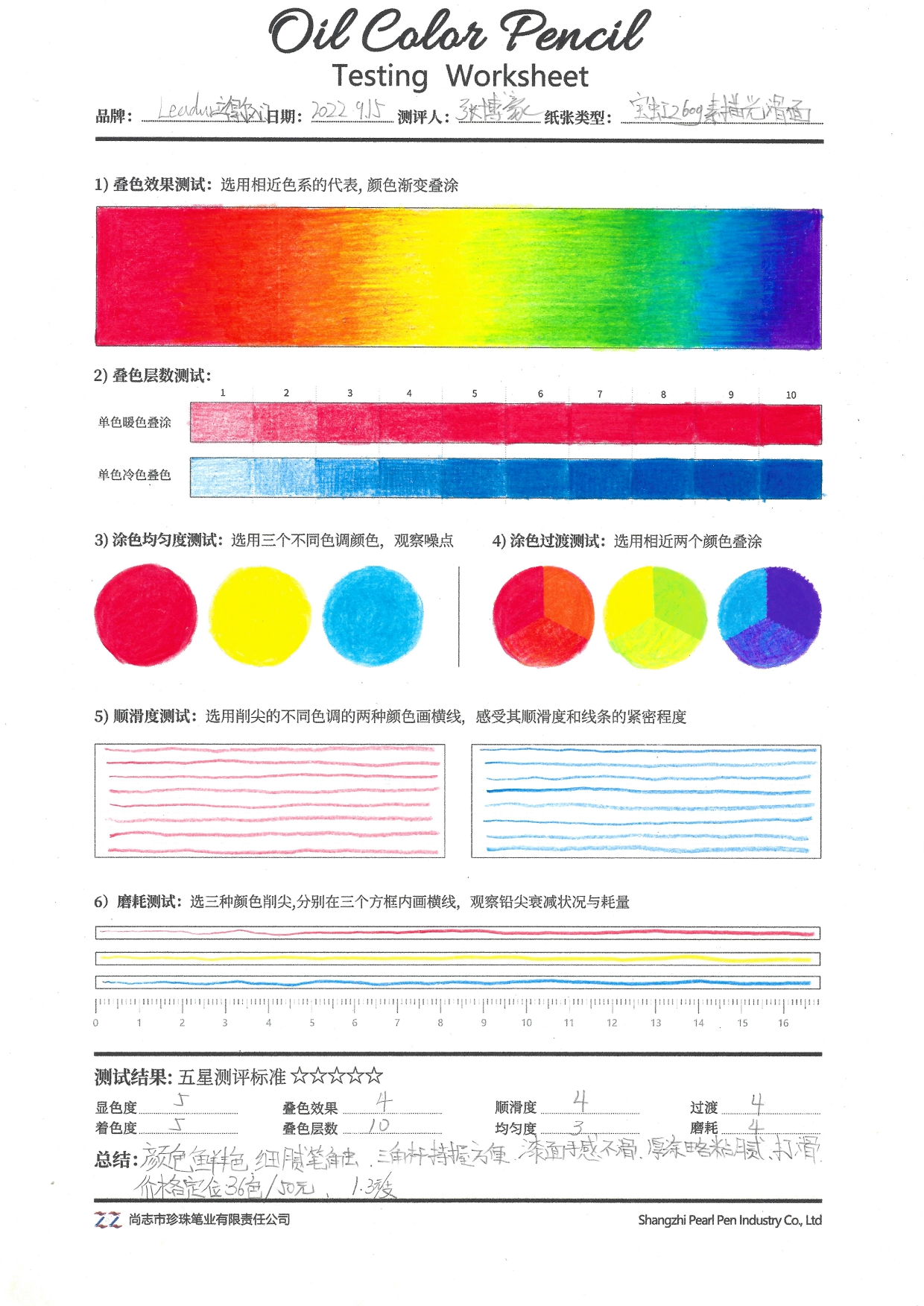

Performance Testing Metrics

We evaluate soft cores against five criteria:

| Characteristic | Industry Standard | Leadur Premium Grade |

|---|---|---|

| Break Resistance | 2.8 N pressure | 3.5 N pressure |

| Color Layering | 7-8 layers | 12 layers |

| Tip Durability | 15 min drawing | 11 min drawing |

| Blendability | 4.5 score | 5.0 score |

| Lightfastness | 5/10 years | 7/10 years |

When our Russian client requested even softer cores, we achieved sublime blending but increased sharpening frequency to some extent—proving that extreme softness4 demands practical compromises.

What Is the Difference Between Soft Core and Regular Colored Pencils?

Walking our factory floor reveals these pencil types diverging at multiple production stages.

Soft cores prioritize high pigment load (35%) and wax richness, achieving vibrant blendable color at the expense of durability. Regular cores emphasize clay-based binders (up to 45%) for precise lines and longevity, sacrificing some color intensity. Both serve distinct artistic purposes equally well.

Eight Critical Performance Contrasts

Our quality lab tests reveal how these differences manifest:

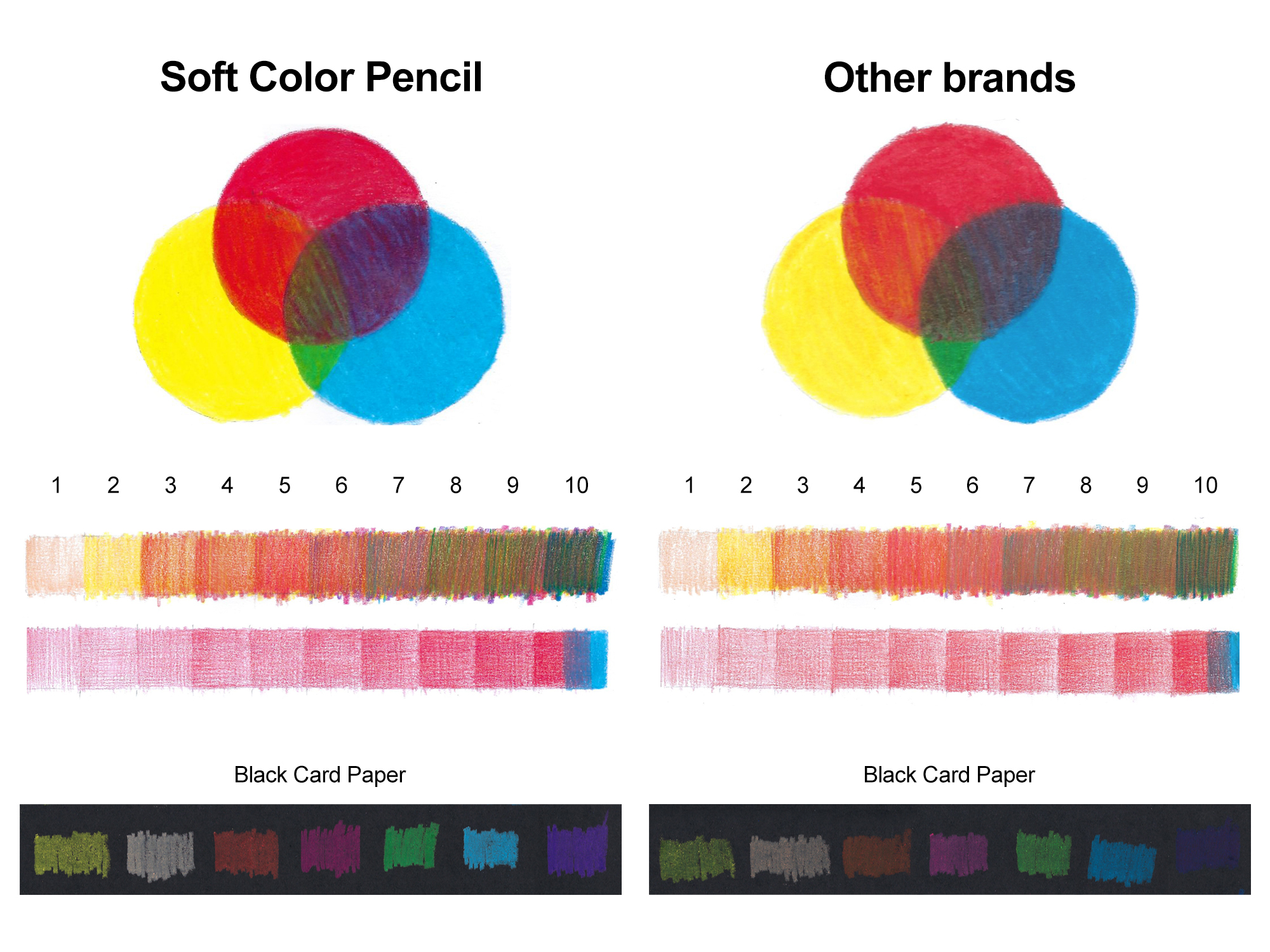

1. Color Expression

- Soft: 98% pigment transfer efficiency

- Regular: 82% pigment transfer efficiency

2. Layering Capacity

- Soft: 10-12 layers without wax bloom

- Regular: 6-8 layers with bloom risk

3. Stroke Uniformity

Soft cores maintain consistency at 40° angles

Regular cores perform better at 65°+ angles

| 4. Tip Stability | Pressure Applied | Soft Core Wear | Regular Core Wear |

|---|---|---|---|

| 200g | 0.8mm reduction | 0.3mm reduction | |

| 500g | Tip deformation | 0.7mm reduction |

5. Production Cost

Soft cores cost 17-22% more due to:

- Higher pigment expense

- Temperature-controlled drying

- Packaging requiring cushioning

6. Lifespan

Regular cores yield 38% more drawing hours

7. Specialty Applications

- Portraits: Soft cores dominate

- Botanical illustration: Regular cores preferred

8. Market Penetration

Soft cores command 85% of professional markets

Regular cores lead in education (62%)

Our Indonesian client's switch to regular cores reduced humidity-related breakage5 in a large part, proving environment affects pencil performance6 as much as formulation.

What Is the Difference Between Hard and Soft Core Colored Pencils?

Extremes define themselves quickly in practice.

Hard cores contain up to 50% binding clay for industrial-grade precision but minimal blendability. Soft cores max out at 15% clay—prioritizing color richness over point retention. Most artists prefer mid-range cores, proving both extremes serve niche needs effectively.

Where Each Excels Professionally

Through client feedback analysis, we've mapped specialist preferences:

Hard Core Applications

- Architectural drafting (0.5mm precision lines)

- Technical illustration requiring scratch-resistant marks

- Lightfast archival work where pigment stability is paramount

- Outdoor sketching demanding durability

Soft Core Domains

- Color blending studies requiring 12+ layer transitions

- Artistic portraiture seeking skin-tone realism

- Large-area coverage projects valuing efficiency

- Studio work with controlled sharpening access

Regional Success Stories

- German engineering firms: Use our hardest cores

- Brazilian comic artists: Blend soft-core varieties

- Japanese stationery lines: Order 60% medium-hard cores

Our French luxury partners prioritize sublime color saturation7 in soft cores despite fragility, while German engineers demand harder cores for drafting work8. Neither approach is universally superior.

Conclusion

Select pencils matching your artistic goals. Core differences create specialized tools, not objectively superior ones. Adapt to local preferences9 for best results.

-

Exploring regional preferences can provide insights into market demands, helping you tailor your offerings effectively. ↩

-

Understanding ultra-soft expectations can help you tailor products to meet specific client needs effectively. ↩

-

Exploring superior color depth can enhance your knowledge of art materials and improve your product offerings. ↩

-

This resource will provide insights into the complexities and trade-offs involved in achieving extreme softness. ↩

-

Understanding the causes of humidity-related breakage can help improve pencil performance and durability. ↩

-

Exploring this topic can provide insights into optimizing pencil design and usage for better results. ↩

-

Explore this link to understand how sublime color saturation enhances luxury products and why it's essential for quality. ↩

-

Discover the significance of harder cores in drafting work and how they improve precision and durability. ↩

-

Explore the impact of local preferences on pencil choices to better connect with your audience and improve your art. ↩

You may also be interested in:

What are the best soft colored pencils for artists?

Are you struggling to find colored pencils that blend smoothly and create vibrant artwork? Many artists waste money on harsh, scratchy pencils that frustrate their creative process. The best soft

Do colored pencils come in different hardness?

You're staring at a box of colored pencils. Your art project needs precise lines and smooth colors. But which pencils should you choose? Yes, colored pencils absolutely come in different

Recommended Articles

What are the best soft colored pencils for artists?

Oct 24, 2025

What kind of paint do you use for mandala painting?

Sep 19, 2025

Do colored pencils come in different hardness?

Aug 26, 2025

Is it possible to make your pencil lead unbreakable?

May 11, 2025

Hello world!

Apr 11, 2025